Botler 1 was first designed on a radio controlled crawler. Its great grip and flexibility was an excellent starting point.

The first, obvious downside was the space available. I had to 3D print two plates in order to host the first electronic circuits. Sadly, as size increased so did the weight (the 3D printed parts were not heavy). The stability started to fall apart, so I had to discard this model.

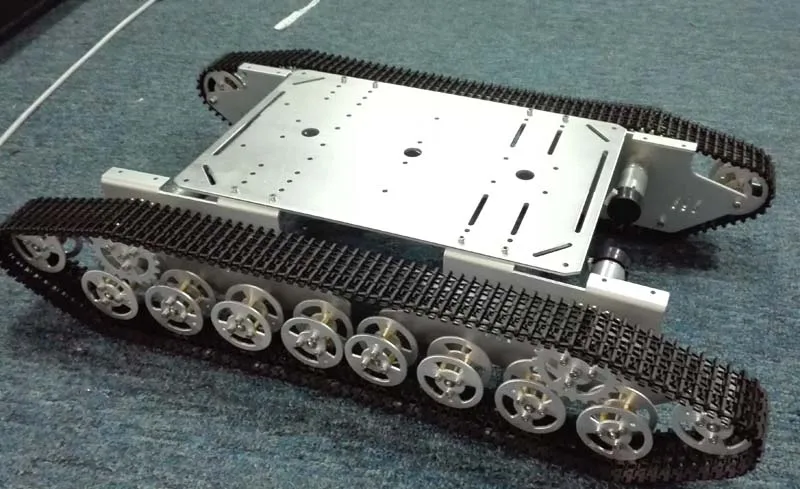

Thanks to China and its cheaper products (If I had to buy everything in Switzerland I wouldn’t be at this point) I found a solid tank chassis. There were dozens of options but finally I got my hand on a Doit T800.

Ok, it may not be the best option but it was cheap. Instructions were not in the box but the seller quickly sent a copy by e-mail.

The T800 is made in aluminium, has a lot of space (even in front and behind, where I quickly 3D printed two extensions) and it is powered by 4 9V motors with hall sensors.

As starting upgrades I got higher torque 12v motors from DOIT and decided to add a ‘floor’ on the platfrom. This last mod will slightly increase Botler 1 arm maximum extent and provide a shell for most electronic components.

I 3D printed the four walls and decided to create a ‘diagnostic bay’. A simple removable door that reveals a ton of plugs. If a software upgrade, flash, debug is required it could come in handy. Instead of opening the exterior shell, navigate trough thousand of wires while hoping to reach the desired component without mistakenly unplugging a hidden wire… it is quicker and safer to have this upgrade.

As added support to the second baseplate I have 3D printed a few pillars 14x14mm with a 6mm hole in the middle. To give a bit more of strength to these pillars I have inserted a hollow aluminium tube. Inside the pillars will pass a M3 rod as added reinforcement.